IM-V Packaging Machine with Volumetric Filler is the most preferred machine in terms of precision and other features. Let’s take a look at the features of IM-V Volumetric Filling Packaging Machine.

Suitable for free fall with IM-V Volumetric Packing Machine; All products whose density (g / cm ^ 3) remain within the desired sensitivity range can be packaged. Filling volume based weight control is made with 6 or 8 volume adjustable containers. Different sizes of containers can be used for different products. Gravity sensitivity depends on the part size and homogeneity of the products to be filled. . Easy change of collar set enables quick package change. All surfaces in contact with the product in IM-V Volumetric Packing Machine are AISI 304 stainless steel and suitable for food.

IM-V Volumetric Packing Machine offers installation in accordance with CE standards. Easy adjustable speckle sensor for precise package length adjustment. Automatic stop operation due to printer error is continuously checked, preventing unprinted and incorrect printing. Film driven unit with AC motor drive. Pneumatic driven horizontal jaw pressing and cutting unit. Depending on the type of packaging, cold or hot bonding techniques can be applied. Film tension is continuously controlled. Coil centering with precise edge control is also available. Different language options and user touch screen are available.

Optional Equipment:

Contact us for different type of packages, products and capacities.

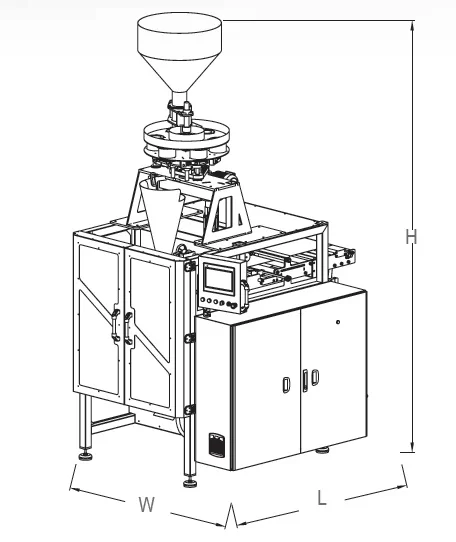

| Width | IM290 1560mm / IM400 1720mm |

| Length | IM290 2050mm / IM400 2050mm |

| Height | IM290 2910mm / IM400 3150mm |

| Weight | IM290 950kg / IM400 1000kg |

| Production Speed (Number/Min) | 75 |

| Package Length | IM290 60mm-350mm / IM400 60mm-700mm |

| Package Width | IM290 60mm-270mm / IM400 60mm-380mm |

| Film Coil Diameter | 300mm |

| Film Coil Width | IM290 130mm-580mm / IM400 130mm-830mm |

| Power Consumption | 7.5 Kw |

| Operating Voltage | 380V 3 Phase 50Hz |

| Air Consumption | 250 Lt/Dakika - Minute |

| Air Pressure (min.) | 5 Bar |

Our Company which founded in 2011 with its experiences in machine production and automation sectors is enhancing with safe steps in the way to be one of the leader engineering company.

Fevzi Çakmak Mah. Artar 5 San. Sitesi

Kenitra Cad. No: 6/1 Karatay / KONYA / TURKEY

+90 332 345 1835

bilgi@harkom.com.tr