The FMQ-W packaging machine is designed for high-precision packaging, ensuring fragile products like sugar are handled with care. Its unique 25% angle incline minimizes product disintegration and breakage during the packaging process. Controlled by an independent microprocessor, this packaging machine offers reliable performance. The touch screen interface simplifies operation for sugar packaging and other delicate items.

This packaging machine supports multiple unloading and automatic product feeding, ideal for sugar packaging and other sensitive products. It features customizable pans and feeding mechanisms, tailored to product type and speed. The packaging machine’s AISI 304 stainless steel surfaces ensure food safety. Quick collar set changes enhance the efficiency of this packaging machine for various package sizes.

The FMQ-W packaging machine uses an AC motor-driven film sliding unit for smooth operation. Its pneumatically driven jaw ensures precise cutting and sealing, perfect for sugar packaging. The packaging machine stops automatically to prevent unprinted or faulty packaging. It supports both hot and cold bonding techniques, enhancing its versatility.

Optional equipment like nitrogen filling and screw feeding units improve the packaging machine’s functionality for sugar packaging. The output conveyor and vacuum belt streamline operations, while the Eurohole/strap hole option adds packaging versatility. A printer with barcode and date capabilities enhances traceability for this packaging machine.

Optional Equipment:

Contact us for different type of packages, products and capacities.

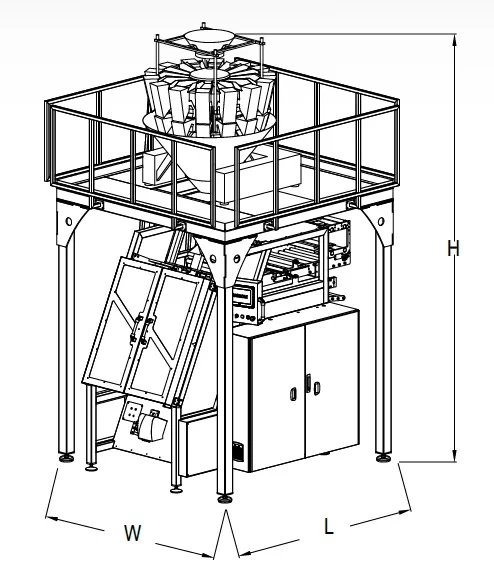

| Width | 2950mm |

| Length | 2500mm |

| Height | 3900mm |

| Weight | 1700kg |

| Production Speed (Number/Min) | 75 |

| Package Length | 60mm - 320mm |

| Package Width | 60mm - 190mm |

| Film Coil Diameter | 300mm |

| Film Coil Width | 130mm - 580mm |

| Power Consumption | 7.5 Kw |

| Operating Voltage | 380V 3 Phases 50Hz |

| Air Consumption | 350 Lt/Dakika - Minute |

| Air Pressure (min.) |