The BM-A Auger Filler Machine is one of the most preferred solutions for spice packaging and all kinds of powder products; as a leading spice packaging machine, it offers exceptional performance. Thanks to its servo-driven Auger Filler Machine technology, it delivers extremely precise and fast filling performance. With its multilingual touchscreen interface, this user-friendly Packaging Machine can be operated easily by anyone. The BM-A Auger Filler Machine significantly increases efficiency in high-volume spice packaging lines.

The Auger Filler Machine controls the exact product weight by counting screw rotations. Manufactured entirely from AISI 304 stainless steel, this food-grade Auger Filler Machine meets the highest hygiene standards. The photocell mark sensor enables millimeter-precise bag length adjustment, making it an outstanding Packaging Machine for consistent results every time.

In case of printer errors, the Auger Filler packaging machine stops automatically to prevent unprinted or faulty packages. Fully compliant with CE safety standards, this reliable Auger Filler Machine is designed for safe operation even in 7/24 production. It is truly a next-generation Packaging Machine that puts operator and product safety first.

All these features make the BM-A Auger Filler spice packaging machine a highly versatile Packaging Machine suitable for various pouch styles and products.

The screw filling machine offers fast, efficient packaging at a reasonable price. Its practical design suits various products and capacities. The Packaging Machine is praised for its reliability and performance. Contact us for tailored screw filling machine solutions.

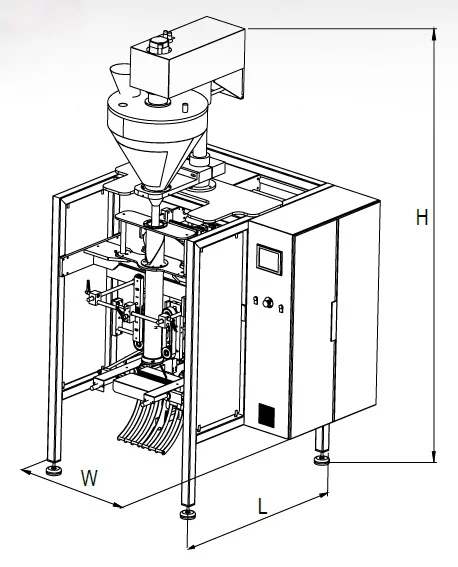

| Width | BM290 1660mm / BM400 1720mm |

| Length | BM290 2050mm / BM400 2050mm |

| Height | BM290 3000mm / BM400 3240mm |

| Weight | BM290 650kg / BM400 700kg |

| Production Speed (Number/Min) | 50 |

| Package Length | BM290 60mm-350mm / BM400 60mm-700mm |

| Package Width | BM290 60mm-270mm / BM400 60mm-380mm |

| Film Coil Diameter | 300mm |

| Film Coil Width | BM290 130mm-580mm / BM400 130mm-830mm |

| Power Consumption | 5.5 Kw |

| Operating Voltage | 380V 3 Phase 50Hz |

| Air Consumption | 150 Lt/Dakika - Minute |

| Air Pressure (min.) |